Jan 14, 2026

Massimo here! Welcome to Episode Six of our GeoJourney series. This is the one we've all been waiting for: dome installation has officially begun, today you’ll see the first hubs bolted into the ground; You will also deep dive with engineers Paul and Kyle into the details of how our first principles approach is reinventing the MEP system (mechanical, electrical and plumbing) that will reside inside the walls of our home.

What You'll See in this Episode:

Installation Progress Amma One hits major milestones with Neil on site: the foundation and stem wall are complete, BoneRock components have arrived, and the first anchor hub has been bolted into place, marking a historic moment as the structure begins to rise.

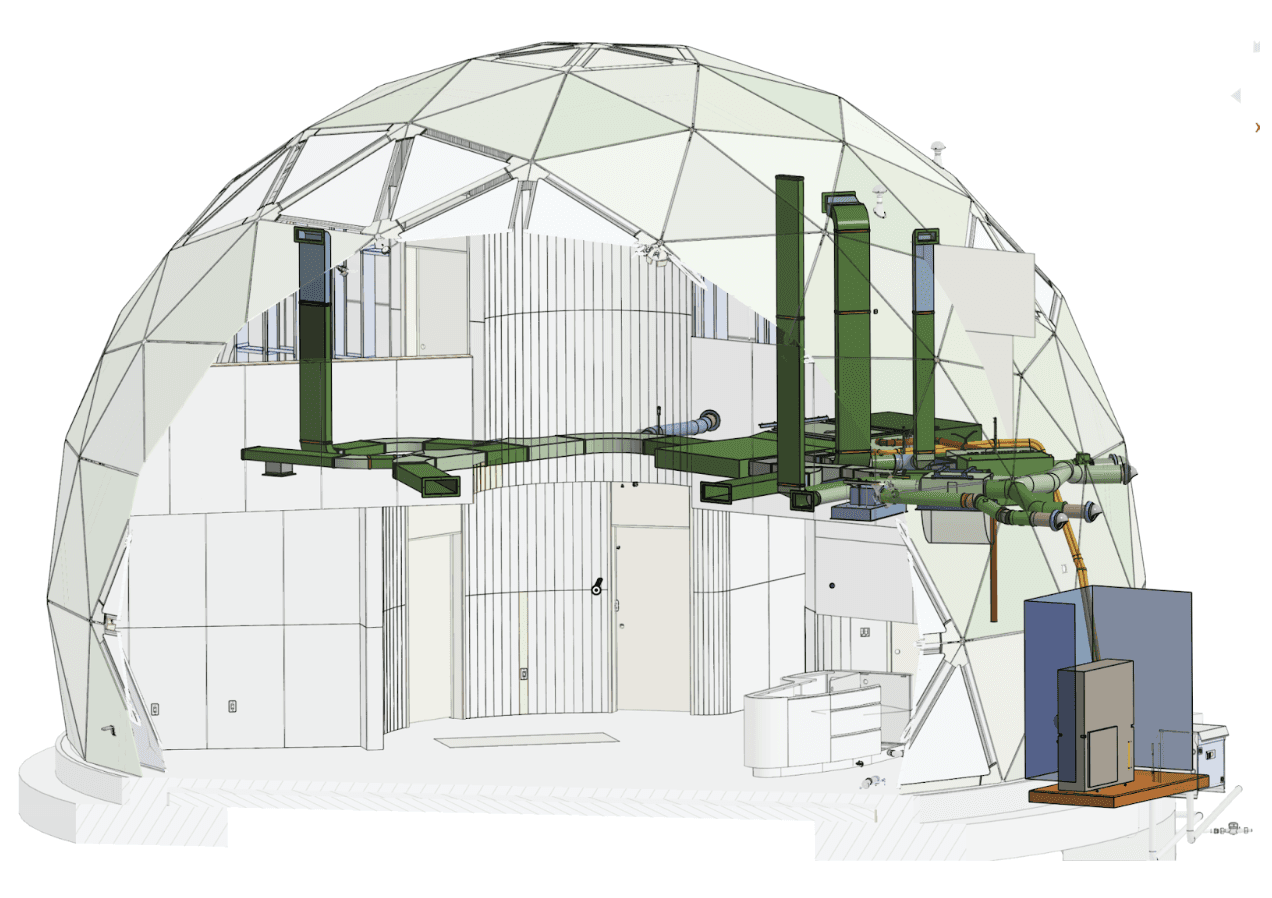

MEP Systems Engineering The engineering team explains how Geoship pre-engineers all mechanical, electrical, and plumbing systems in CAD. This approach eliminates on-site guesswork and reduces installation time from days to hours through modular, plug-and-play design.

Amma One Installation Update: From Foundation to First Hub

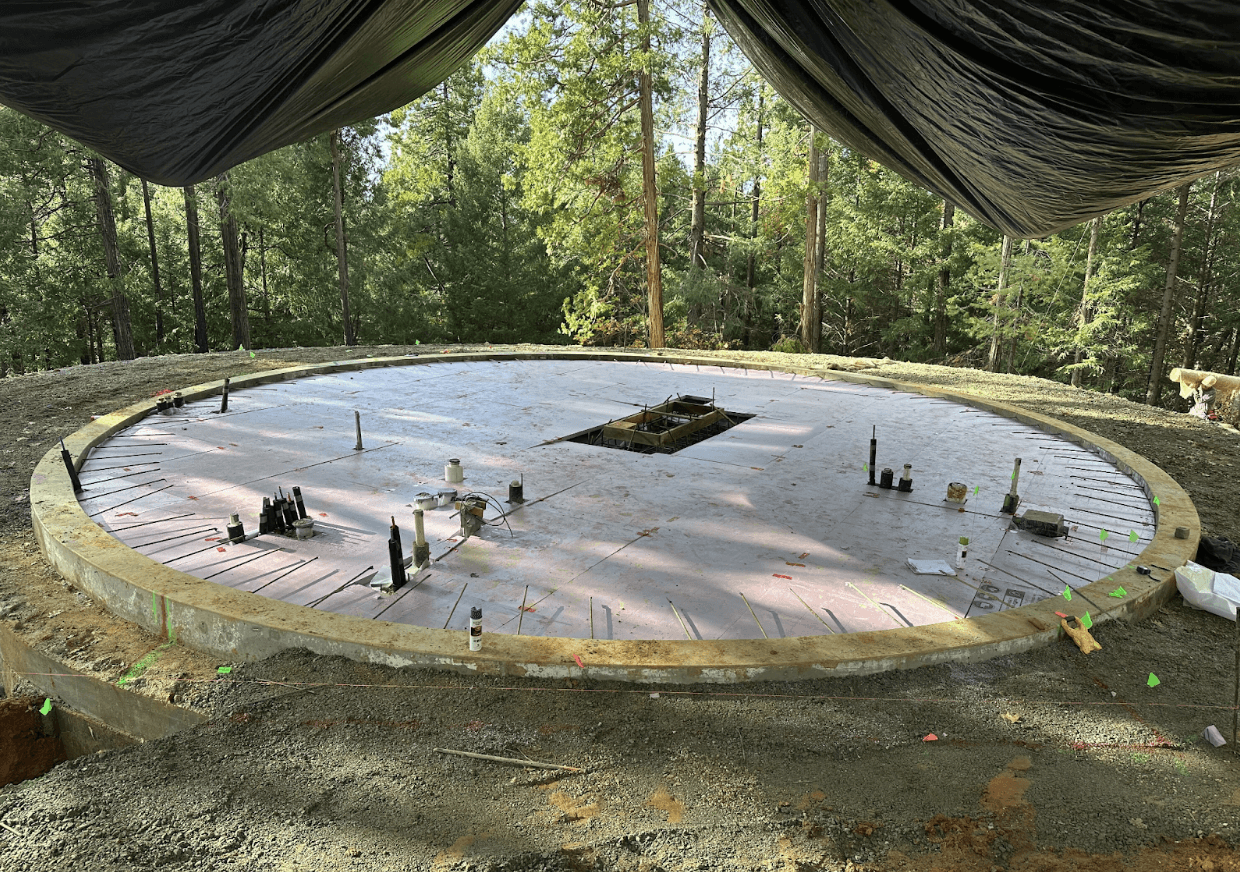

The foundation phase reached completion with a carefully orchestrated sequence: soil compaction created the stable base, utility inspections verified all underslab plumbing and electrical, and rebar placement reinforced the structure. The team then poured the foundation slab and stem wall in coordinated pours, creating the precise platform where Amma One's geodesic skeleton would anchor. With the concrete cured and the foundation ready, the stage was set for the dome structure to rise.

Stem wall in place, utilities poking through the foundation, concrete slab ready to be poured.

Neil Decker, our install lead, has been guiding the install team through cold, rain and unexpected obstacles with relentless passion. These guys are really working in difficult conditions but the motivation to push forward has won every challenge so far.

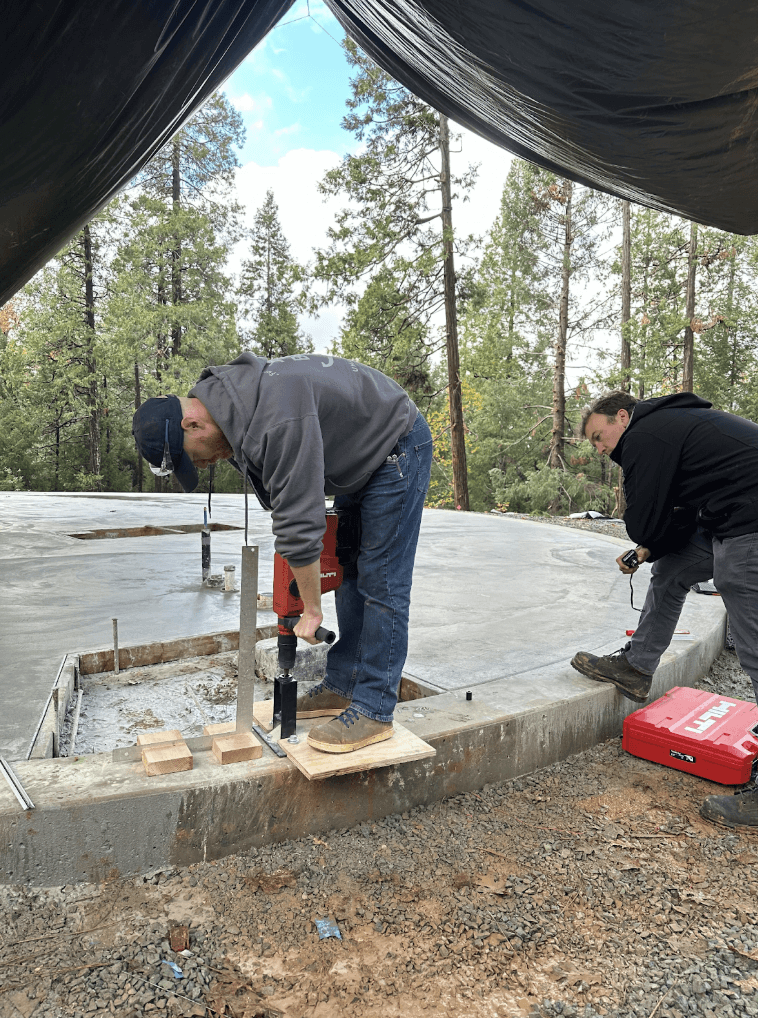

"We decided to put up a giant tarp to cover the whole site, so we could divert the rain and continue working under 5 inch rainfall winter thunderstorms. Just yesterday, we got a drill bit stuck as we were trying to get through almost two feet of concrete. We came up with a creative solution to weld a threaded rod onto it so we can use washers and mechanical advantage to pull it back up. These are just some of the challenges that we run into on a daily basis here, building Amma One for the first time; but we're getting through it and we're being creative and that's part of the fun." says Neil after a hard day of work.

Quick Overview on the Foundation Process:

The team started by trenching for utilities: water, electric, and sewer lines connecting to the existing commercial building on site. After cutting concrete and digging the trench, they backfilled with sand before laying pipes. Once utilities were in place and inspected, they moved to the foundation pour.

The stem wall (the foundation element where the dome structure sits) was poured along with the footing. This created the stable platform for the struts and hubs that form the dome's skeleton. After the stem wall cured, the team installed underslab utilities including all drain lines and water supply lines before pouring the four-inch concrete slab in a single day.

Installing the Anchor Hubs:

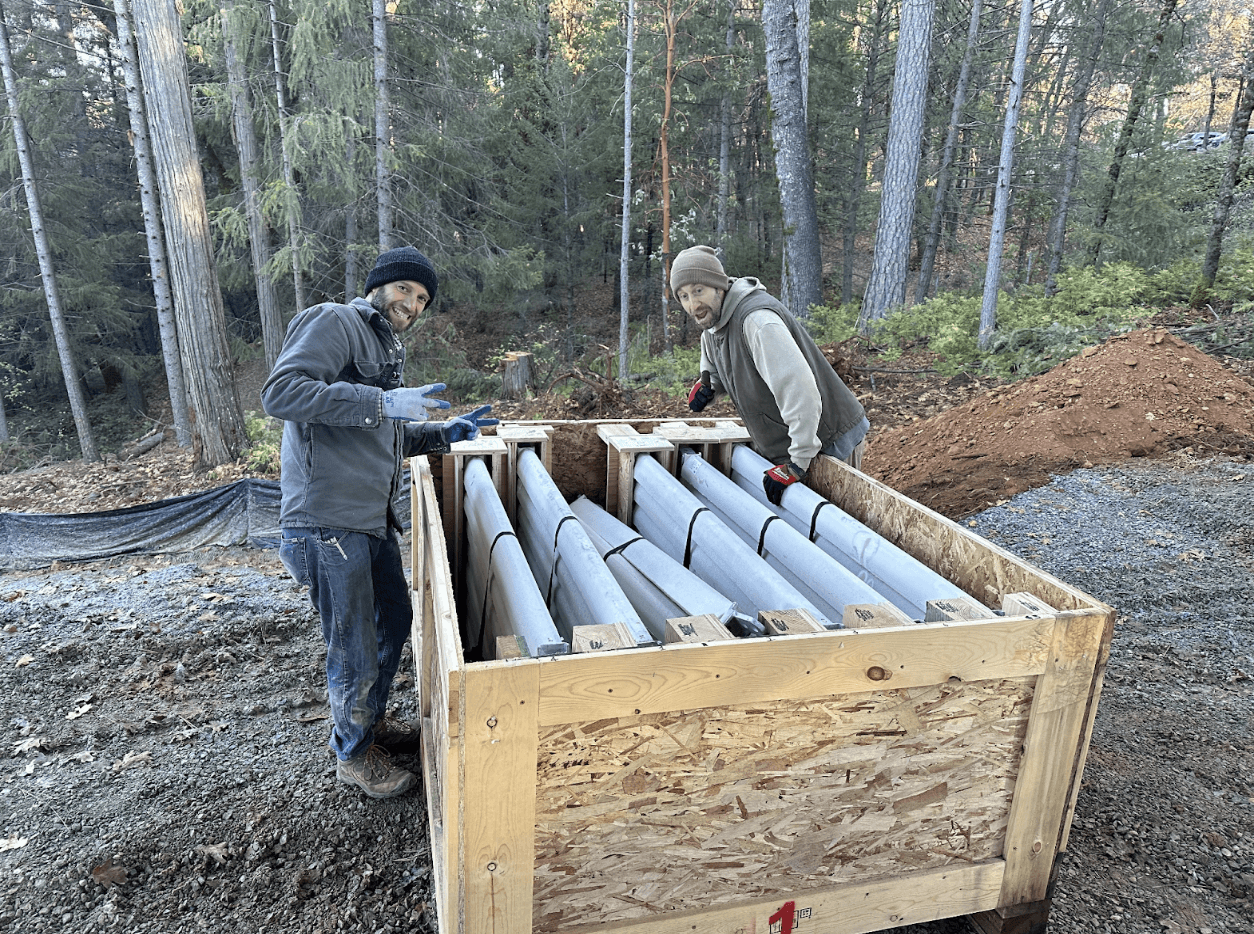

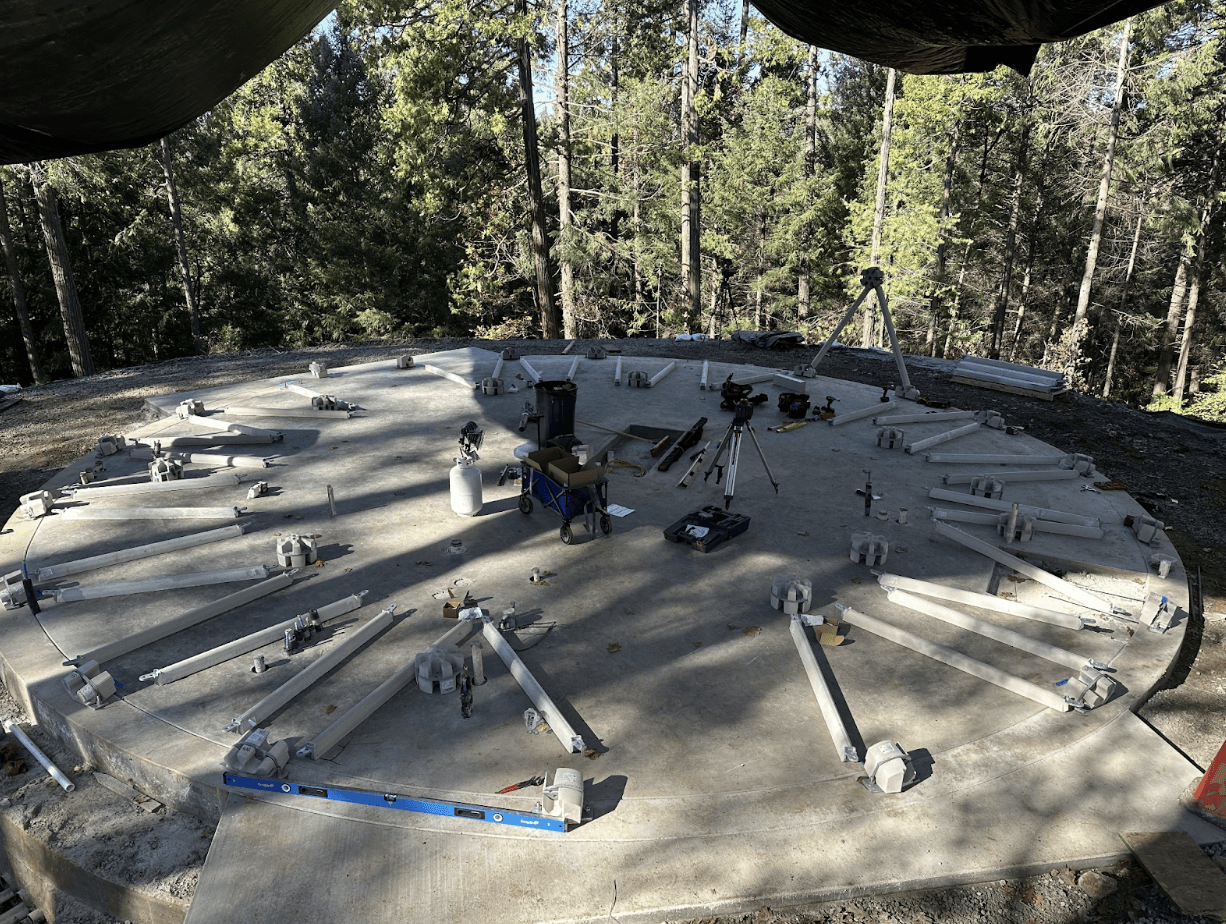

With the foundation complete, the team received the BoneRock components in just 11 crates to complete the dome's bone structure, pre-arranged in installation sequence. No sorting required: parts move directly from crate to staging area to installation, with each strut secured by a single bolt in minutes.

The first two crates of BoneRock parts get delivered by Ryley and the excitement is high.

BoneRock crates arrive on site. All parts fit in just 11 crates

Aldo and Sam are happy to see all parts have been arranged in order of installation

The team is starting with anchor hubs and anchor struts to form the first circle. These are the parts that form the critical connection points between the foundation and the dome structure. This process requires extreme precision because all the geometry of the house stems from these anchor points.

The process looks like this:

Drill 27-inch-deep holes using drill guides to ensure perfectly perpendicular alignment

Blow out each hole with compressed air to remove dust and aggregate

Inspect holes to verify they're clean and properly sized

Fill holes with structural epoxy

Insert threaded rods with shims to maintain exact positioning during cure

Remove shims once epoxy has cured

Bolt anchor hubs securely in place

Casey carefully drilling the concrete with this engineered “guide” overlooked by engineer Jason

Anchoring the Hubs

The anchor hubs form the first row, half-circle pieces that connect directly to the foundation and support everything above. Once these critical connection points are secured, the geodesic framework builds upward rapidly.

Years of engineering are now transforming into a physical structure you can walk inside. The dome is rising, and from here, the outer shell will take just a handful of weeks to complete. Stay tuned for more updates and footage as construction accelerates.

Engineering MEP Systems as a Product

While installation progresses on site, there's another critical piece of engineering we are revealing today: the complete MEP (mechanical, electrical, and plumbing) systems that make Amma One a functional home.

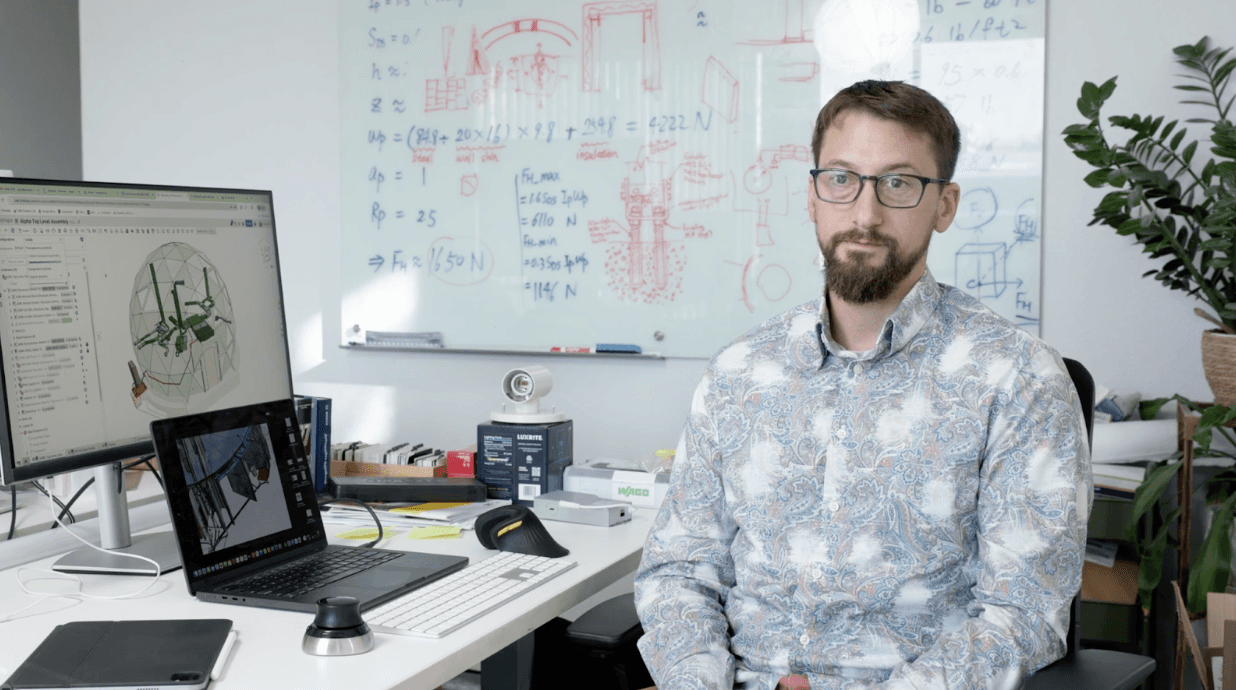

Paul Choin, Head of Product Engineering, brings the same precision and systems thinking from his work at Tesla, Honda, and Apple to designing how you'll interact with every system in your home: from heating and cooling to lighting and plumbing.

"Geoship doesn't want to give a customer an empty shell. We want to have it be a complete home, which includes the MEP. That's the HVAC system, the plumbing, and the electrical system. So we turn lights on, you can flush toilets. It's a full product."

— Paul Choin

Why This Matters:

In conventional construction, MEP systems are often figured out in the field. Electricians, plumbers, and HVAC technicians make decisions on site about routing, placement, and connections. What looks good on 2D drawings frequently creates conflicts in reality: water pipes interfering with electrical lines, ducts positioned poorly, and other clashes that cost time, money, and generate significant waste.

The result? Homes with light switches in awkward spots, vents that blow cold air directly on your head, water pipes you can hear every time someone flushes a toilet upstairs, and systems that require specialized knowledge to service or repair.

Geoship is taking a different approach:

"We want to be able to make the system easy to assemble. So onsite, that means no cutting or measuring. It means that we have to think of everything upfront, lay it out in CAD, understand the lengths of hoses, lengths of pipe, length of electrical wire, and make things click together so that way you're assembling things and not constructing them."

— Paul Choin

How It Works:

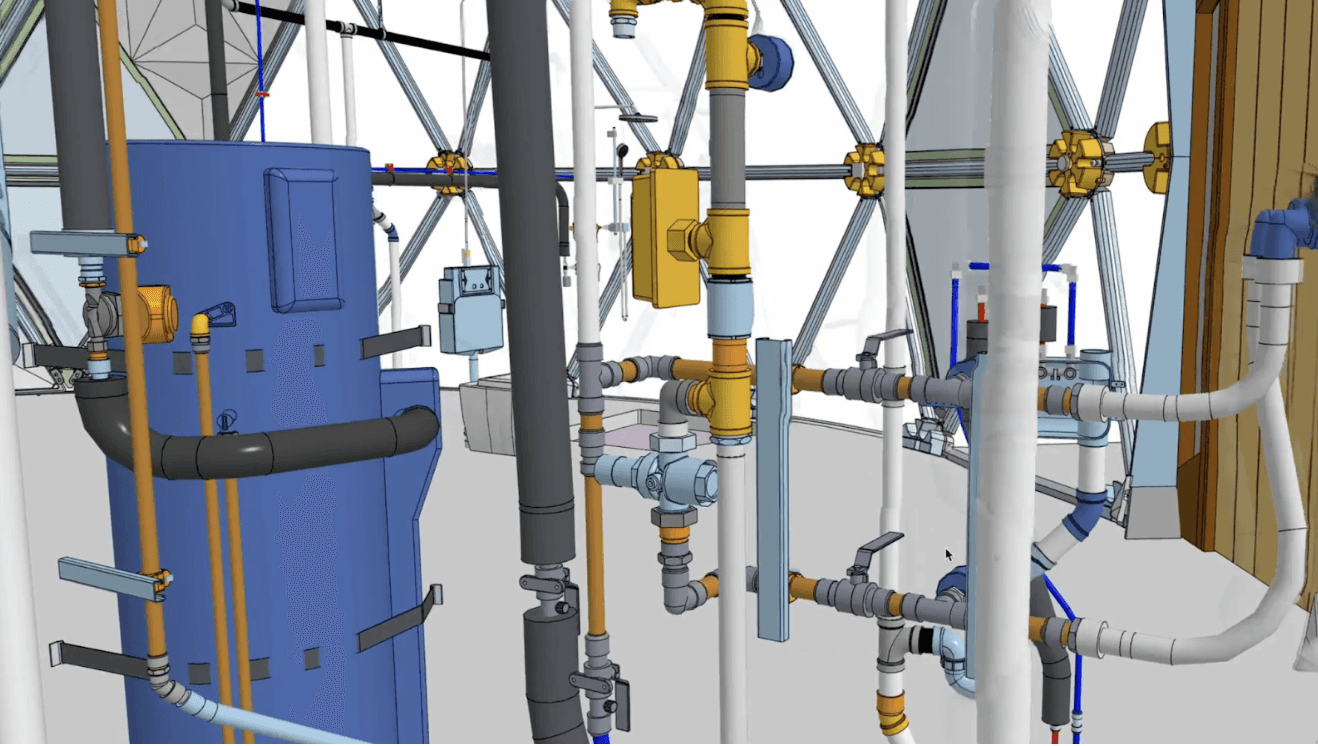

The CAD design of the HVAC system on Amma One

Plumbing System: Components are pre-assembled in the factory with fewer connection points needed on site. Everything arrives with exact specifications. The hot water system is designed using circulation valves at each sink that maintain temperature without wasting energy.

Electrical System: Outlets arrive with connectors already attached. Installation is simply clicking matching components together and routing according to the drawings. What traditionally takes days can be completed in hours.

HVAC System: The dome uses a highly efficient ducted mini-split heat pump combined with an Energy Recovery Ventilator (ERV). The heat pump's outdoor unit connects to an indoor unit via refrigerant lines, delivering conditioned air through ducts. The ERV ensures excellent indoor air quality and efficiency by exchanging air while recovering energy.

The indoor main unit lives on the loft floor with easy access for filter changes and maintenance. Every duct, every vent, every connection point has been designed to integrate seamlessly with the dome's geometry.

Part of the Plumbing on Amma One

What Does "Home as a Product" Actually Mean?

Engineering the home as a product means designing once to building many.

Kyle, Geoship's senior engineer, has helped many building sites and explains:

"When traditionally you're putting these things together, might work out really nicely on a 2D paper, but as soon as you get into the field and start to route it (in the tight spaces inside the walls n.d.r.), you realize, oh geez, I didn't think about that. This water pipe is now going through this electrical line. But if we think about it ahead of time and find those clashes in our CAD models, it takes away any of that kind of guesswork."

— Kyle

The advantages go far beyond just efficient installation. Our modular systems are designed to be easily maintained, even without specialized expertise. This streamlined installation process allows for the production of better homes more quickly and affordably. As with any manufactured product, the economics improve with scale. We see this as the essential change needed to make regenerative housing widely accessible, as we simply cannot hand-craft our way to lower home costs.

Higher Quality: Every decision has been made deliberately, every conflict resolved before installation begins. Nothing is improvised or "good enough."

More Affordable: Reducing installation time and complexity while maintaining exceptional quality allows Geoship to create better homes at lower costs.

Easier Installation: Site work becomes assembly rather than construction, requiring less specialized knowledge and reducing labor costs.

Modular and Serviceable: Systems are designed to be maintained, upgraded, and repaired without requiring specialized expertise. Components can be replaced without tearing into walls.

"Creating something that is seamless to install also requires less specialty skills to maintain so down the road, you have a system that's modular, a system that's very serviceable."

— Kyle

Building the Future, One System at a Time

From the first anchor hub bolted into the foundation to the engineered MEP systems being finalized, every element of Amma One represents a fundamental rethinking of how homes can be built.

The installation team is solving real-world challenges on site like adapting to weather, creatively overcoming obstacles, and proving out the assembly process. Meanwhile, the engineering team is ensuring that every system works seamlessly together, creating a home that's efficient, maintainable, and built to support the people living inside it for generations.

I am so grateful to have had once again the opportunity to pull back the curtain on Geoship's go-to-market journey, bringing you closer to both the installation of our first customer-ready dome and the people and processes shaping this amazing adventure in real time.

Many of you have been following this journey from the beginning, supporting us through investment, dome reservations, or simply believing that we can build better. Thank you for being part of this transformation. The first dome is rising, and we're building this future together.

Massimo Massarotto

Geoship Team