Nov 12, 2025

Massimo here! Welcome to Episode Four of our Geojourney series. This one's for those craving the specifics: what goes into the engineering and validation processes that allow us to approach manufacturing and installation with confidence.

My role at Geoship is as a production associate, working hands-on in the factory alongside the team bringing this vision to life. I'm excited to take you behind the scenes where you can see firsthand everything that goes into rethinking the home from first principles and engineering it as a product. I believe this kind of transparency matters, and no one has done this before so I'm here to bring you deeper context beyond what you'll see in the episode.

In this series, we're pulling back the curtain on Geoship's go-to-market journey, bringing you closer to both the installation of our first customer-ready dome and the people and processes shaping the future of regenerative living.

A Look Inside Our Engineering Process & Install Updates

What You’ll See

In this episode of The GeoJourney, we're taking you inside cross-departmental collaboration between our engineering, manufacturing, and install teams. You'll meet Paul Choin, head of engineering, who walks us through the development process from concept to production, and Jason Hill, our lead manufacturing engineer, and see his work in action through what we're calling "Mockup 2.0," where ideas become 3D-printed models and then full-scale tests.

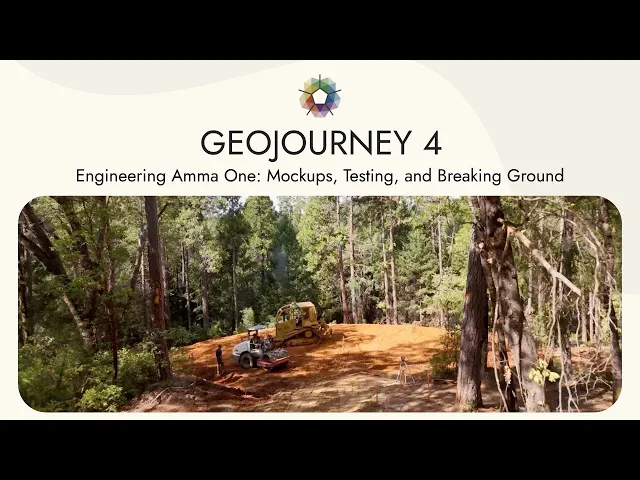

Then we head to the Nevada City site to catch up with Neil Decker, our install lead, where foundation work for our first customer-ready Amma dome, Amma One, has officially begun.

From Concept to Construction

In this episode, we sit down with Paul Choin, the Head of Product Engineering, to break down how his team brings designs to life.

Paul brings a distinguished career advancing eco-friendly technologies and vehicle efficiency from his work at Honda, Tesla, Apple, and Zoox (Amazon). Now as Geoship's Head of Product Engineering, he's applying that same innovative mindset to rethinking how we build homes.

Right now, the Geoship engineering team is hyper-focused on finalizing component designs and getting them into production as quickly as possible. Once a part design is "released," the specs are locked in and the production team can begin refining manufacturing processes to build it efficiently and at scale.

Watch Episode 2 to learn more about our first customer and first build site.

Paul breaks down this complex, iterative development process into a simple overview:

"We'll make a mold, cast some parts, and put them together in a mockup environment (like the Slice or Mockup 2.0 you'll see in the video.) From there, we can see how everything goes together and fits, which allows us to make rapid process changes. We go through the same development process for each of our components before releasing parts." — Paul Choin

The typical development process looks like this:

Every component starts as a design idea, then becomes a CAD file

The CAD file gets printed as a 3D model

These printed parts create a prototype that answers questions about individual components and how they interact with each other (a quick way to validate the design, but not the only one needed)

Once the 3D mockup is validated, the design goes to production

Production quickly casts enough parts to run real-life accuracy tests in the full-scale mockup while figuring out how to manufacture at scale

This rapid iteration loop between design, models, real parts, and assembly brings team leads into the thinking tank multiple times a day

Learnings from each phase flow back to engineering, and the loop starts again until every detail works seamlessly and all the kinks are worked out.

Testing in 3D

You'll also hear from Jason Hill, our lead manufacturing engineer, on how he tests components first as 3D prints, then as full-size parts on the mockup.

Jason Hill brings over a decade of automotive mass manufacturing experience from Toyota and Lucid Motors, where he specialized in bringing new products from design to mass production and commissioning new product lines. At Geoship, he applies this expertise at the crucial intersection of engineering, manufacturing, and installation, transforming dome concepts into scalable, efficient production systems and ensuring that theoretical designs work when built at full scale.

In the episode, you'll hear Jason say:

"This has never been done before. We've never assembled this design of home before, in fact, no one has. To better understand how it's going to work, we 3D print 1-to-6 scale models of the dome to see how the different parts go together correctly, incorrectly, and what sequence they need to follow to be efficient and accurate." — Jason Hill

Building something that's never been built before means our engineers live in the world of open-ended problems, where solutions emerge through discussion, experimentation, and intentional pauses to think deeply.

Maybe it's no coincidence that three of our engineers are ultra-marathon runners. The same patience and endurance that carries you through 100-mile races seems to show up when you're inventing a new way to build homes.

The Purpose of Mockup 2.0

In Episode 1, we showed you ‘The Slice,’' our Mockup 1.0. The Slice was specifically designed as an ongoing living lab to test how components interact, primarily the structure and loft floor connections.

In this episode, we introduce you to Mockup 2.0, affectionately called 'The Eiffel Tower.' It serves a similar function to Mockup 1.0 but focuses on how the structure interfaces with the foundation and first floor of the dome. This full-scale version of Jason's 3D printed models is our testing ground for anchoring the base to the cement foundation, assembling the first two layers of hubs, struts, and skins, and verifying the accuracy of position, leveling, and radius of each component.

The Eiffel Tower, our Mockup 2.0 site with anchor hubs bolted on the concrete foundation and struts connecting them (left) and added exterior skins (right)

After the install team assembles the parts, they use advanced 3D scanning tools to measure each component against the digital blueprints. This process confirms real-world functionality and precise tolerances. The resulting data either validates assumptions or highlights necessary changes, ensuring these insights inform all subsequent developments.

Once the loop is resolved and a solution agreed upon, manufacturing shifts focus to scaling production of the finalized parts. This process is detailed in another blog post: The Production Line is Running, The Team is in a Rhythm, and the First Amma Dome is Assembled.

Install Progress Updates:

The Groundwork for Amma One is well under way and this is what it looks like:

The team is now moving full steam ahead to prepare the foundation.

To create the foundation, the build team has cleared the area, raised and flattened the pad, and is now compacting the soil with precise moisture levels to create solid, stable ground. An inspector visits the site to certify each layer before work can continue. Once the pad is shaped and firm, the team will proceed with the footing (a ring where the dome will stand) and then pour the cement foundation.

About Our Foundation: The dome foundation is engineered as a unified, reinforced, and highly stable platform designed to last for generations. Unlike conventional foundations that can shift, crack, and require ongoing maintenance, this foundation works in harmony with the dome's geometry to stay solid over time. It also pairs with a high R-value structure, supporting stable interior temperatures that keep the home cooler in summer, warmer in winter, and far more energy-efficient year-round.

What's Next: Upcoming Foundation Milestones

Site work requires careful execution, but it's generally the "easy" part. Over the coming weeks, the team will complete several key steps to prepare the foundation for Amma One:

Install plumbing and utility supply lines

Pass under-slab utility inspection

Lay vapor barrier, gravel, and insulation

Prepare the slab and install rebar reinforcement

Pass rebar inspection

Pour the concrete slab

Taking the Time to Do It Right

Because this is our first customer-ready dome, we're taking our time to ensure every single step in this process is validated, inspected, and tested. We've built in time for reworks and optimization so that we can be certain this dome, and the domes to come, are the best they can be.

Getting our factory-built housing certification, which we covered in Episode 3, was a major milestone that ultimately took a bit longer than expected. Working in tandem with regulatory and inspection offices for this initial dome has required patience but their attitude and help has been really helpful. Now that we have it, the process will be more streamlined going forward.

We're also building during the rainy season, which has given us a unique opportunity to problem-solve for installation in wet conditions. A significant storm this week delayed work for a few days, but in this fire-prone region, we're grateful for the rain. The delays bring valuable learning that will make future builds more resilient.

Here's the important context: This first dome is intentionally taking longer to complete because we're building, prototyping, and completing all third-party testing and reviews simultaneously. Our long-term goal is to reduce installation time to closer to a month (depending on site prep requirements) and accomplish it with far fewer people once our process has been fully iterated and refined. Reducing labor costs, speeding up timelines, and still delivering a high-quality home are the goals we're working toward as we scale to make regenerative living accessible.

Honoring the Land, Building the Future

Before any clearing or prep work began, we held a private blessing for the land, asking for permission to build and seeking the blessing of the local Indigenous community, for whom we also undertake this work. We brought forward our written intentions, hoping to infuse them into this site. We're working every day with a higher purpose, and approaching the site, you can feel the energy and possibility in the air.

Many of you have been following our journey for a while, and several of you have helped fuel our progress through investment, dome reservations, or by showing up as ambassadors. We want to make sure you get a front row seat to where it all began. It's exciting to be making history together.

WIth gratitude,

Massimo Massarotto

Geoship Team