Aug 1, 2025

Howdy folks! Massimo Massarotto here, bringing you an exciting update from the Geoship production factory. We're marking a major milestone that brings us one step closer to delivering the first Amma Dome to our customer, and I’m excited to share all the details with you.

I’m committed to giving you an inside look at the hard work, challenges, and breakthroughs happening right now as we move closer to turning our vision into reality.

Let’s dive in!

An Exciting Progress Update!

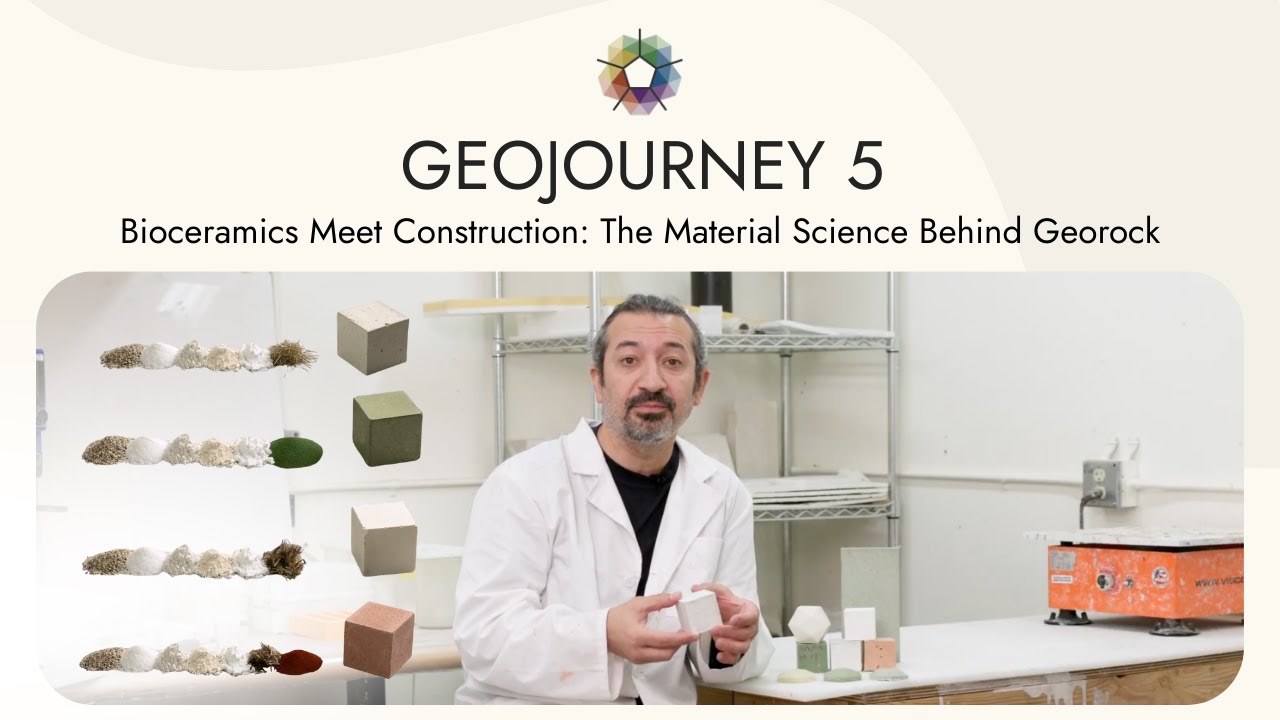

If you’ve been with us for a while, you know the journey. You believed early when Geoship was still a bold idea—a regenerative, disaster resilient dome home made from bioceramic. Over the past year, we've made substantial strides. We’ve tested domes in the real world, developed a new kind of patent pending bioceramic (GeoRock), and opened a pilot facility to bring production in-house.

We’re excited to announce that we’ve moved beyond prototyping and are officially producing the parts for the first Amma Founders Edition Dome, set for installation for our first paying customer. We are no longer just testing concepts, we’re now building real customer domes and perfecting the systems that will allow us to scale production and deliver many more.

I interviewed our Head of Marketing, Lauren Russo, to get her perspective on the significance of this milestone for our community of investors and future customers.

She explained that while this is a major announcement, it’s also one that has been eagerly anticipated. Lauren emphasized that every step we've taken has been purposeful, focused on one goal—“nailing it.”

“For many, it may feel like this has been a long time coming, especially if you’ve been following our journey from the start. But at Geoship, we’re not rushing to the finish line. We’re taking a measured, structured approach rooted in our philosophy of 'pilot it, nail it, scale it.' The focus we’re placing on 'nailing it' is what we believe will truly set us apart and enable us to create a paradigm shift in how homes are designed, built, and purchased. More than just rethinking construction, we aim to elevate the entire home experience, reshaping expectations for what a home can be."

Lauren says underscoring that while our ultimate goal is mass manufacturing on a global scale, what matters most to us right now is getting the product and the production process right.

"This vision, this product, and, more importantly, our future customers—who are truly craving something radically different—deserve this approach."

Introducing Our Production Framework: "Gear 1," "Gear 2," and "Gear 3"

At Geoship, we use a simple framework to describe the evolution of our manufacturing process: Gear 1, Gear 2, and Gear 3. Each "gear" represents a distinct phase in ramping up our factory, increasing throughput, and moving from pilot production toward scalable dome manufacturing.

Gear 1:

In Gear 1, we focused on building the foundation—setting up the pilot facility, installing key systems, and debugging everything. This phase was about creating the infrastructure for what’s to come.

Gear 2:

Gear 2 is about perfecting the process. We’re now running consistent production with repeatable output, building the parts for our first customer-ready Amma Dome. It’s a phase of refinement and optimization.

Gear 3:

In Gear 3, we focus on scaling efficiently. We’ll upgrade technology, integrate more automation, and improve systems to significantly increase speed, reduce costs, and scale production to meet demand.

Each gear builds on the last. We're currently in "Gear 2," and we'll provide more context on this phase throughout the update!

Reflecting on Gear 1: Building a Production Line from Scratch – A Year of Foundational Problem-Solving, Rigorous Testing, and Satisfying Progress

To truly understand why this early stage of production deserves such celebration, we need to look at where our pilot production process began

When most people think of 'production,' they imagine a flip of a switch, and machines humming to life. But for us, the journey has not been that simple. When we moved into our new facility a year ago, the space was an empty room—no equipment, no systems in place.

The past year has been all about building from scratch: designing the layout, ordering machines, many of which were commissioned to be custom-built, and laying the groundwork for testing and refining a production process for a new product that has never been mass-produced before.

Once the pilot production facility was operational, every aspect of the dome production process, from dry material handling to mixing, casting, demolding, and packing, had to be developed, tested, and refined by our team. Each step has been a process of invention, adaptation, and continuous improvement.

I sat down with Andrew James, Geoship’s VP of Manufacturing, to get his perspective on what it has been like to create a custom production process from scratch over the past year, where we stand now, and where we’re headed next.

“This production line isn’t like a machine you just turn on and expect to run the same way every time; there’s a lot of nuance. That’s what makes it feel alive.”

Andrew explains. And when you step into the space, you can feel it—the line is humming, the production team is fully engaged, and the vision is finally in motion, creating the very first parts for the first customer ready Amma Dome.

Andrew’s experience in fast-paced environments like Tesla and Kindred AI has been crucial in shaping Geoship’s production line. He brought expertise in commissioning equipment, debugging systems, and integrating automation. At Tesla, he thrived in high-pressure manufacturing, and at Kindred AI, he worked on robotics integration. This background has enabled him to lead our production ramp, from system setup to scaling production.

Building something no one’s ever built before is no small feat. There’s no guidebook, no step-by-step manual to follow.

“We experiment, we adjust, we talk to each other constantly—and somehow, it’s working. That’s the magic,”

Andrew shares with a touch of dreamlike excitement. It’s this spirit of constant learning and collaboration that has fueled our progress.

Where we are now: The Work Rhythm of “Gear 2” Production

Over the past few months, we’ve been focused on successfully passing rigorous factory housing certification tests. We've cast and tested parts under extreme conditions—snow loads, impact resistance, tensile strength, and hurricane conditions. The effort has paid off. We’ve confirmed the engineering and chemistry behind every key component.

With the tests complete, the engineering team released the final part designs, and production quickly followed. We’re now focused on producing the critical components for the first customer-ready "Amma Founders Edition" dome. We’ve started with the struts and hubs, followed by the exterior skins and interior walls.

This marks the start of "Gear 2"—the middle phase of our production strategy. Gear 1 laid the foundation, and now Gear 2 is focused on scaling production and refining our processes. This is a huge milestone, and we’re excited to see our vision taking shape.

Since transitioning into Gear 2, our production line has developed a steady, cyclical rhythm—a process that feels almost like a heartbeat, purposeful and consistent. To give you an inside look at our day-to-day, here’s what the rhythm of a typical production run looks like now that we’re fully up and running:

The process begins with preparing the molds and rolling them along the newly completed conveyance route, an important upgrade to our facility that boosts both efficiency and precision.

Once the molds are in place, we mix the GeoRock and cast batches of five parts back-to-back, ensuring consistency with each batch.

By the end of the day, the freshly cast parts rest in their molds, ready to cure overnight, maintaining the steady flow of production.

Each day, we seamlessly continue where we left off. The process begins with demolding the parts cast the day before. It’s a precise and rewarding step, as each part is carefully released and sent through Quality Control. Some parts emerge perfectly, while others provide valuable insights that help us fine-tune and optimize the process daily.

After demolding, we meticulously inspect and organize the finished parts. This operation involves a visual inspection and 3D scanning to analyze the thickness, shape, surface, and color of each part, ensuring the highest quality control.

Lastly we store and secure parts into crates—like pieces of a larger puzzle—each one ready to play its role in the Amma Dome. Then the cycle repeats, with new molds and fresh batches of GeoRock, continuously refining our production rhythm.

We’re continuously optimizing our production process—fine-tuning material consistency, improving surface quality, and refining the workflow. While some molds and days perform better than others, the team is empowered to make quick adjustments, keeping the process moving forward. There's a strong culture of collaboration and improvement, and the excitement is growing as we move closer to our goals.

Just to put things into perspective, Andrew specifies:

“We went from barely getting one part out at a time to running a full line of mega-molds (molds that cast up to 6 parts at once). That shift didn’t come from a single breakthrough — it came from a hundred small improvements, mostly from the people on the floor.”

It’s been fascinating to watch and be part of the interplay: not just in how the engineers are refining the machines, but in how the production team is growing in experience, confidence, and flow. The whole operation is running smoother and faster than before. But even with those gains, there’s still a strong reliance on our operators. The skill, timing, and attention to detail continue to make a real difference in the outcome of each part.

On the Horizon: The first customer ready Amma Dome and the start of “Gear 3”

With Gear 2 expected to wrap towards the end of this year, we’re only months away from our biggest milestone yet—the installation of the first Amma Founders Edition Dome. This will mark the culmination of 7+ years of R&D and testing, and we can't wait to invite you to witness this monumental moment.

Looking ahead to 2026, we’ll move into Gear 3 — an improved version of this line that allows us to double output and reduce cost per dome.

This includes designing and ordering new equipment, reconfiguring the line layout for a more continuous flow, and incorporating curing ovens and automated conveyance systems to accelerate production. Finally, team members will be trained into more specialized roles.

We're not rushing this, as Gear 2 is teaching us what works, and we will only scale what's proven.

Speaking Personally:

As someone deeply involved in this journey as a member of the production team, I want to say that we feel both the weight and excitement of the progress we are making. It's incredible to think that the work we’re doing now is leading to the first Geoship home installation that will be a reality in the very near future —a moment made possible by the grassroots passion and funding of hundreds over the last 8 years.

We’re filled with gratitude for the unwavering support of our investors, team, and community. We’re on the edge of something truly transformative, and we’re so thankful that you’re part of it.

Thanks for your support and more updates soon,

Massimo Massarotto