Dec 11, 2025

Massimo here! Welcome to Episode Five of our GeoJourney series. Today we're diving deep into the material science behind GeoRock, our bioceramic composite that's designed to outlast conventional building materials by centuries. How do you engineer something that's naturally fire resistant, water resistant, and built to last 500 years? Let's find out.

In this series, we're pulling back the curtain on Geoship's go-to-market journey, bringing you closer to both the installation of our first customer-ready dome and the people and processes shaping the future of regenerative living.

What You'll See in this Episode:

Amma One site progress with Neil: the footing, plumbing trenches, electrical lines, and stem wall that create the base for our first customer-ready dome

Meet Dr. Ali Ozer, Geoship's lead material scientist, and discover how two decades of bioceramic innovation in medical and dental applications is now revolutionizing home construction

Inside the material science lab: watch Dr. Ozer's rigorous process of formulating, testing, and refining each of our four proprietary GeoRock composites

The science behind the materials: a breakdown of what makes each bioceramic unique and how they work together to deliver superior strength, longevity, and resilience

Amma One Installation Update

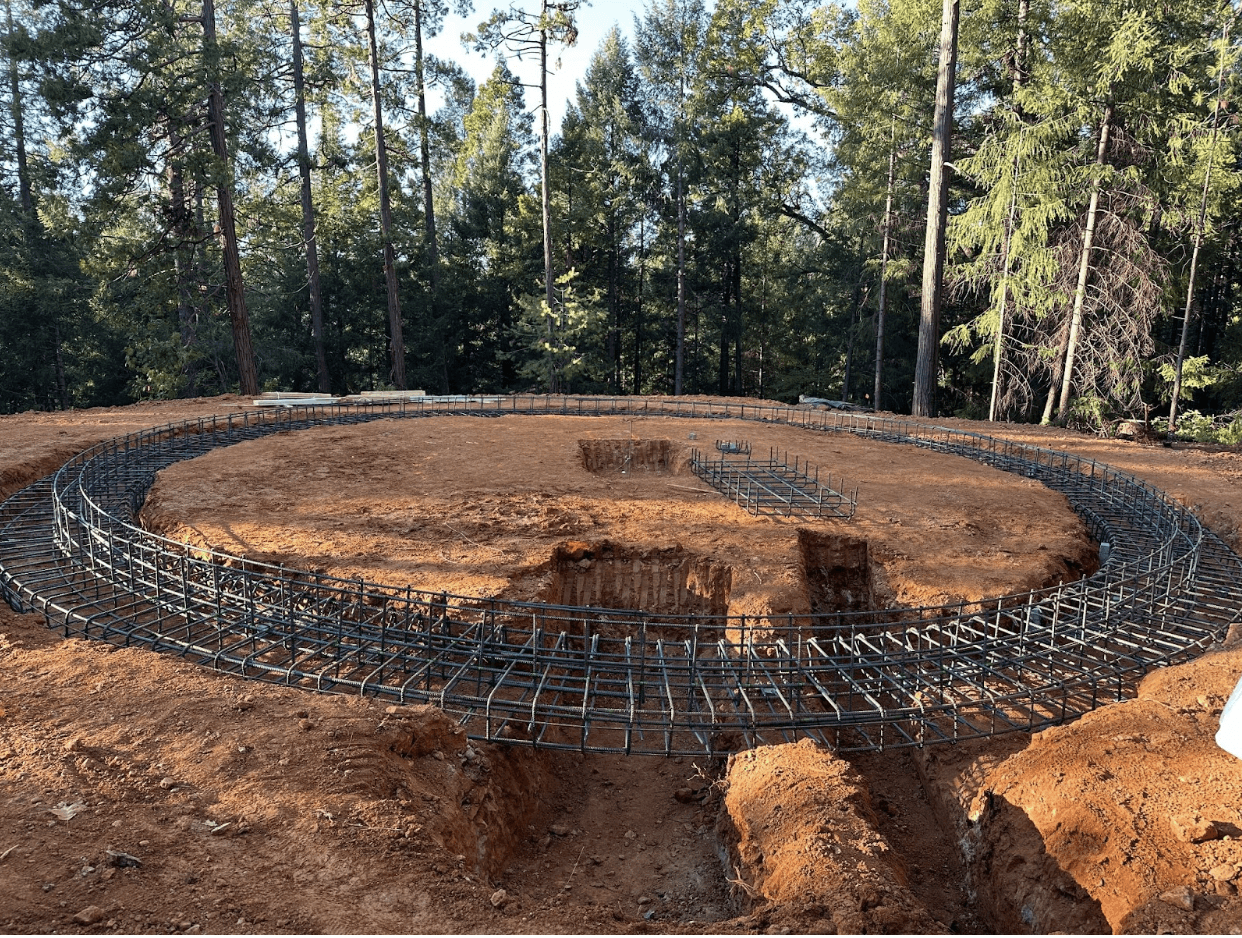

Back at the Nevada City site, foundation work for Amma One is progressing steadily. The team has completed soil compaction, they are working on the rebar skeleton to then pour the concrete.

“This foundation will be a beast” says Neil, with a grin of satisfaction on his face. While our dome structure uses GeoRock bioceramics, the foundation uses reinforced concrete for specific engineering reasons. Concrete provides the compressive strength needed to support the dome's loads while remaining stable in direct contact with soil. It's also the industry-standard material that building inspectors and structural engineers are familiar with, which streamlines the permitting process. In other words, the foundation serves as the anchor point ensuring structural integrity while meeting all code requirements.

Amma One site ready for cement slab foundation

The installation crew, led by Neil, has been making progress on the foundation preparation detailed in Episode 4. They have already excavated the footing and are now preparing the rebar for the foundation and the cement stem wall. Following this, the plumbing and electrical supply lines will be brought in toward the center of the Dome.

Once the foundation is prepped here are the last steps to finish the foundation:

First, we'll pour the gravel to establish the base.

Next, it's critical to complete the vapor barrier for protection.

Then, we will pour the cement slab to form the actual foundation.

Finally after the cement cures, we can begin the installation of the actual Amma One components

Despite challenging weather during this process, with over 5 inches of rain, the excitement was such that our team pushed forward anyway. Although wet and cold, we’ve been gaining momentum. Once the concrete is poured and cured, we cannot wait to begin assembling the first actual dome components, the base hubs from which Amma One will rise.

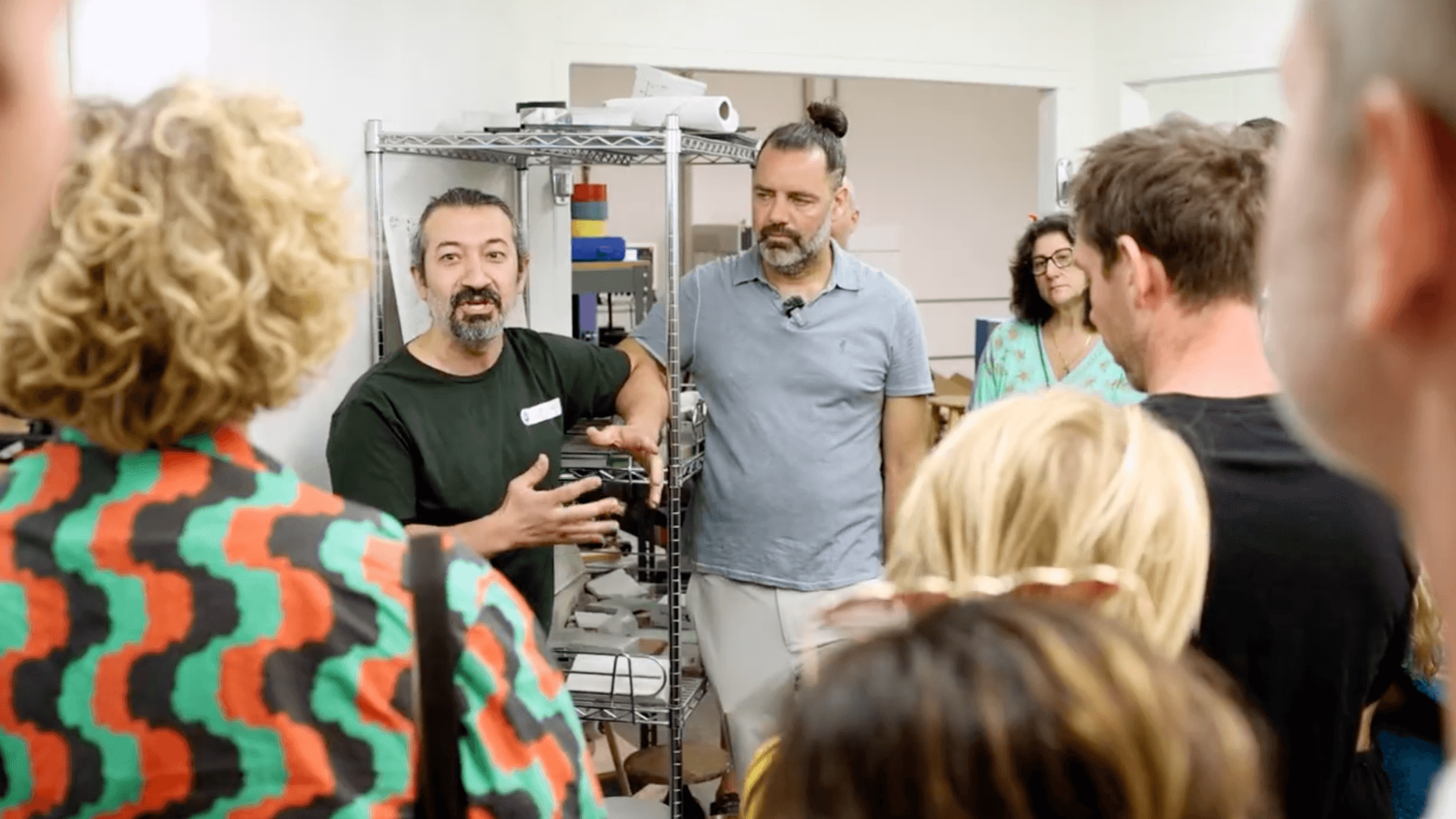

From Biomedical Innovation to Building Innovation

Dr. Ali is one of those bright, kind humans whose mind moves faster than his words. His laugh is explosive and contagious, echoing across the Geoship floor at any moment. He's perpetually in a good mood and ready to joke around, but his expertise is serious: 24 years in material science with a PhD focused on calcium phosphate-based ceramics. His career took him from Turkey to the University of Illinois, then Purdue, then back to UIUC, working on everything from biomaterials to nuclear alloys. In 2024, he joined Geoship as Lead Principal Material Scientist, earning an O-1 'extraordinary ability' visa for his work.

"I wanted to use those materials for the construction of the house as if I were building and constructing a body." — Dr Ali Ozer, Lead Principal Material Scientist

Dr. Ali's journey began with frustration. As an Associate Professor in Turkey, he wanted to pursue sustainable materials research but faced resistance. The focus remained on concrete and fossil fuels. So he came to the US seeking an environment where he could develop materials that give back to the Earth rather than deplete it. Over the following years, he published more than 200 scientific articles and co-authored several books while working at leading research institutions. His work eventually led him to Geoship, where Morgan and Bas were already experimenting with the very materials he'd spent decades refining. The fit was natural.

His approach is rooted in biomimicry: studying how living organisms create strong, durable structures using simple chemistry. Bones and seashells achieve their strength through helical symmetry and continuous growth at minimal energy cost. Dr. Ali saw an opportunity to replicate that process for construction materials.

What Are Bioceramics?

Bioceramics are materials originally developed for medical applications: hip replacements, dental implants, and bone grafts. Each category has a distinct relationship with living tissue: some dissolve over time (biodegradable), some actively promote bone growth (bioactive), and others remain stable but compatible (bioinert).

“Bioceramics can be classified into three categories: bioinert, bioactive, and biodegradable. Each behaves differently with living tissue, and that's what makes them so versatile for different applications." — explains Dr. Ali, and the fascination in his expression draws you in.

Dr. Ali's innovation was adapting these principles for construction. Instead of burning limestone at 2,700°F to make Portland cement, bioceramics mineralize water into crystalline compounds at room temperature, mimicking how nature forms coral and seashells.

Morgan saw the potential for these materials to finally bring Buckminster Fuller's vision to life. He explains how geopolymers and bioceramics represent a fifth family of materials, uniquely combining properties of ceramics, cements, and epoxies.

"Like ceramics, bioceramics are highly crystalline with strong bonding. Like cement, they're powder mixed with water, but they cure at room temperature instead of requiring energy-intensive heat. Like epoxy, they form strong molecular bonds with themselves and with other materials including metal and wood."

The chemical composition (magnesium, calcium, phosphate) mirrors bone material. These compounds are non-toxic and commonly used in fertilizer. Early research suggests these crystalline materials may support plant growth, seed germination, and potentially even human biological functions like heart rate variability and brainwave patterns, though we're still in the early stages of measuring these effects.

This represents a new architectural paradigm: homes that actively support wellbeing rather than compromise it.

Why does this matter in practice for the housing industry:

Traditional concrete production accounts for 8% of global CO2 emissions. (World Economic Forum (2024) It requires extreme heat, creates toxic byproducts, and breaks down within decades. GeoRock takes the opposite approach: it's carbon-negative, uses abundant earth materials, requires no high-heat kilns, and gets stronger over time as it continues to mineralize.

The material has remarkable properties:

Fire resistant to 1,382°F

Fully waterproof and impact resistant

Withstands earthquakes and floods

UV-resistant with a projected lifespan of 500+ years

Carbon negative throughout its lifecycle

These aren't theoretical benefits. They're measurable, tested, and validated through in-house lab work and third-party certification.

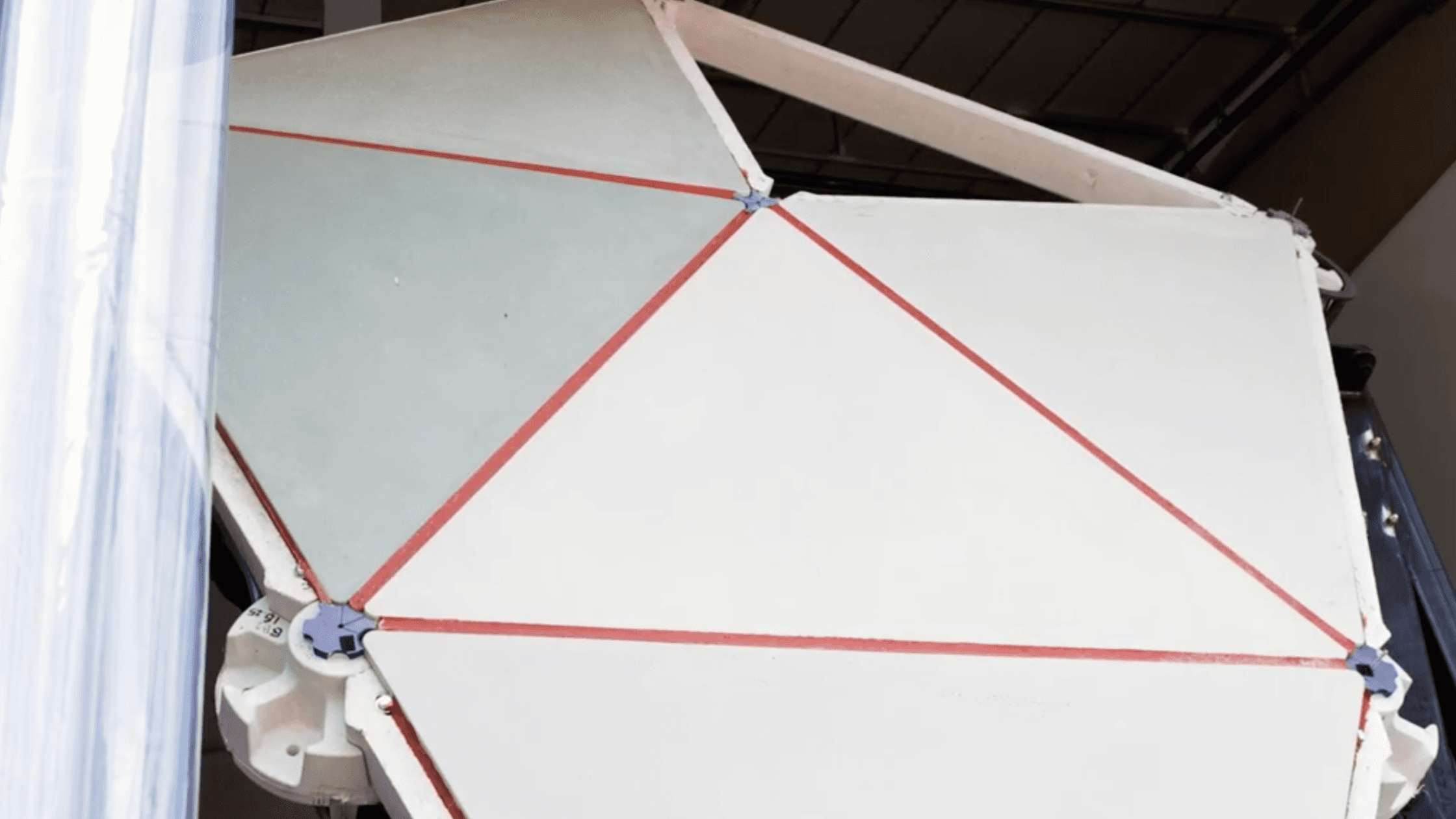

The GeoRock Family: Four Materials, One System

GeoRock is a growing family of specialized formulations, each engineered for specific dome applications. Ali's team spent years perfecting the ratios, fiber implementations, and curing processes.

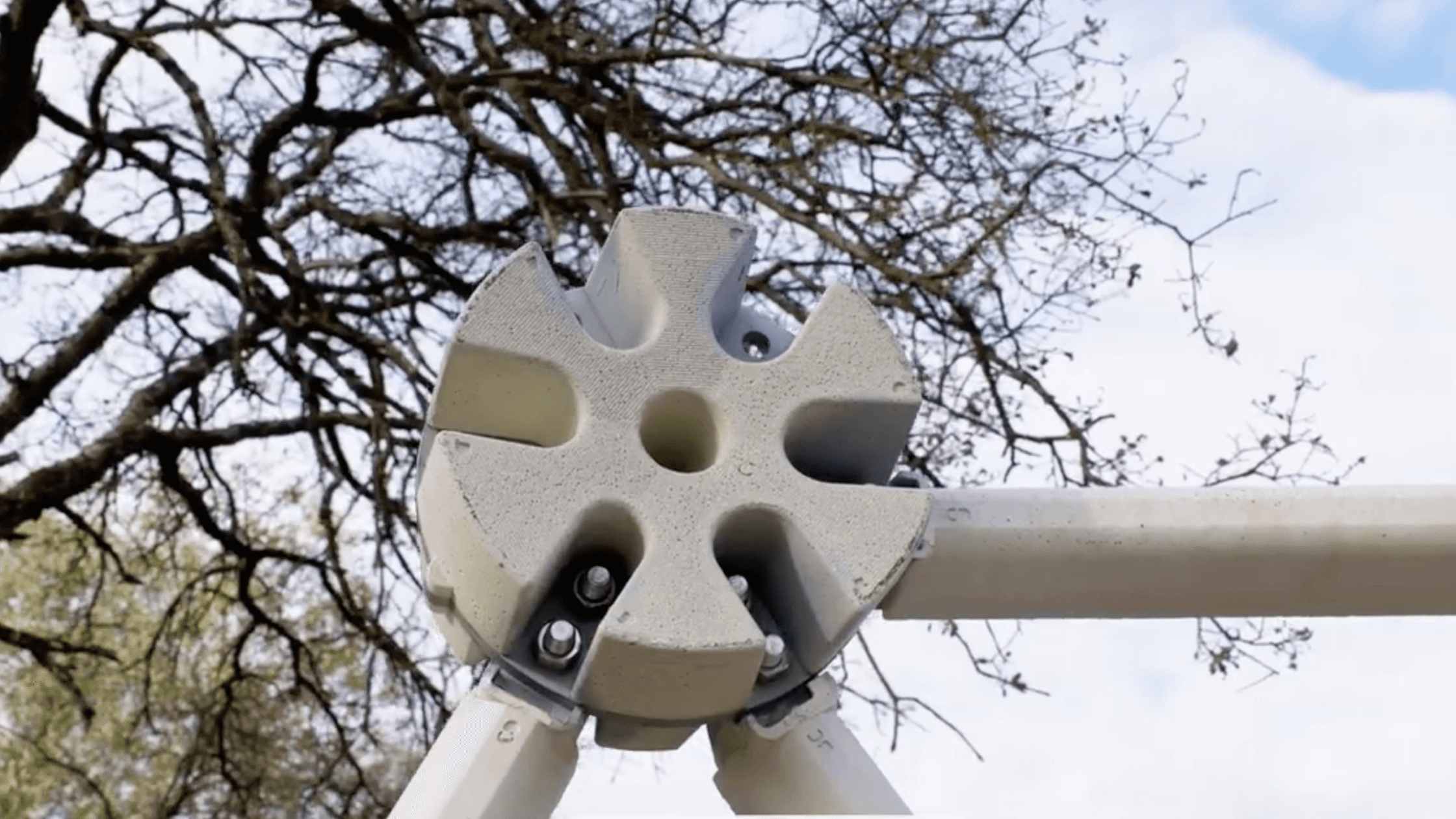

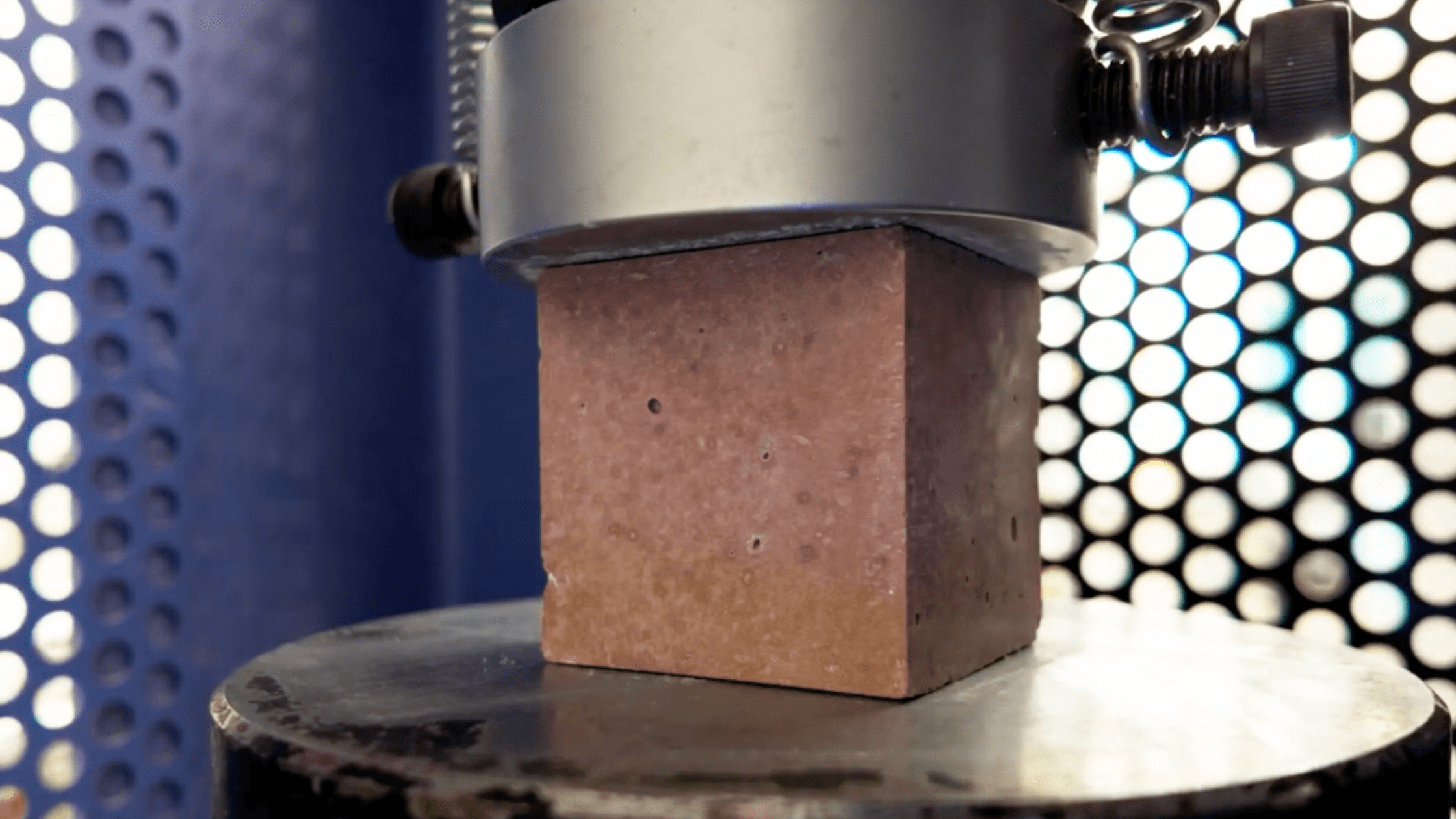

BoneRock: The Structural Skeleton

Weaving a small brick with his hand Dr Ali explains:

"This bone rock that's in my hand is just like our bones. This is the skeleton of our Geoship home and it has the highest durability."

BoneRock is the foundation material, providing both compressive and tensile strength with its metal-ceramic composite structure. The unique flowability makes it ideal for casting complex foundation components.

ShellRock: The Protective Exterior

We have decided to produce the exterior skins mixing in a green color drawn from the leaf of the Manzanita Tree, a common plant here in California to help the dome blend with the natural surroundings.

Manzanita Tree

Ali shows a slighter heavier sample explaining:

"This is a special iteration of GeoRock…that is used for exterior skins, it is fire resistant to 750 degrees C (1382* Fahrenheit). It's water resistant. It doesn't allow water to pass through and it's impact resistant—for example if a tree falls on it. It's also flood resistant and earthquake resistant. It has a very high UV exposure resistance which we've designed to span its life to 500 years."

ShellRock forms the outer shell with exceptional flexibility and impact resistance. It includes integral inorganic pigments that can easily customize the color of the dome in the future, and is reinforced with ceramic basalt scrim mesh. The combination creates a material that blocks water but allows vapor transmission, preventing moisture buildup but can still hold a tree crashing on it. The 500-year lifespan projection is based on accelerated UV degradation testing and material science analysis which blew our minds; we all wish we could live long enough to see it with our own eyes!

LightRock: The Versatile Interior

"Light rock is our most versatile material. It can be super light, just like cotton and it can float on water. We can apply that material to make interior skins, ceiling, floor, or insulation materials." — Dr Ali

LightRock is engineered to be 30-40% less dense than BoneRock or ShellRock while maintaining structural integrity. Its porous structure provides excellent sound damping and thermal insulation. The natural ivory color eliminates the need for paint, and adding chopped basalt fibers improves crack resistance.

BondRock: The Seamless Connector

BondRok serves as both adhesive and joint material, sealing seams between the exterior skins and the hubs/struts bone structure. Its flexibility comes from partially replacing water with a biocompatible natural organic solution, creating crosslinking that provides water resistance and thermal expansion capability without cracking.

The bond strength is extraordinary. In testing, ShellRock panels broke before the BondRock seam did, meaning bond strength exceeds 10,000 PSI, higher than aerospace-grade epoxies. When building structures designed to last 500 years through earthquakes and extreme weather, that molecular bonding makes the difference between separate parts and a unified system.

Testing and Validation

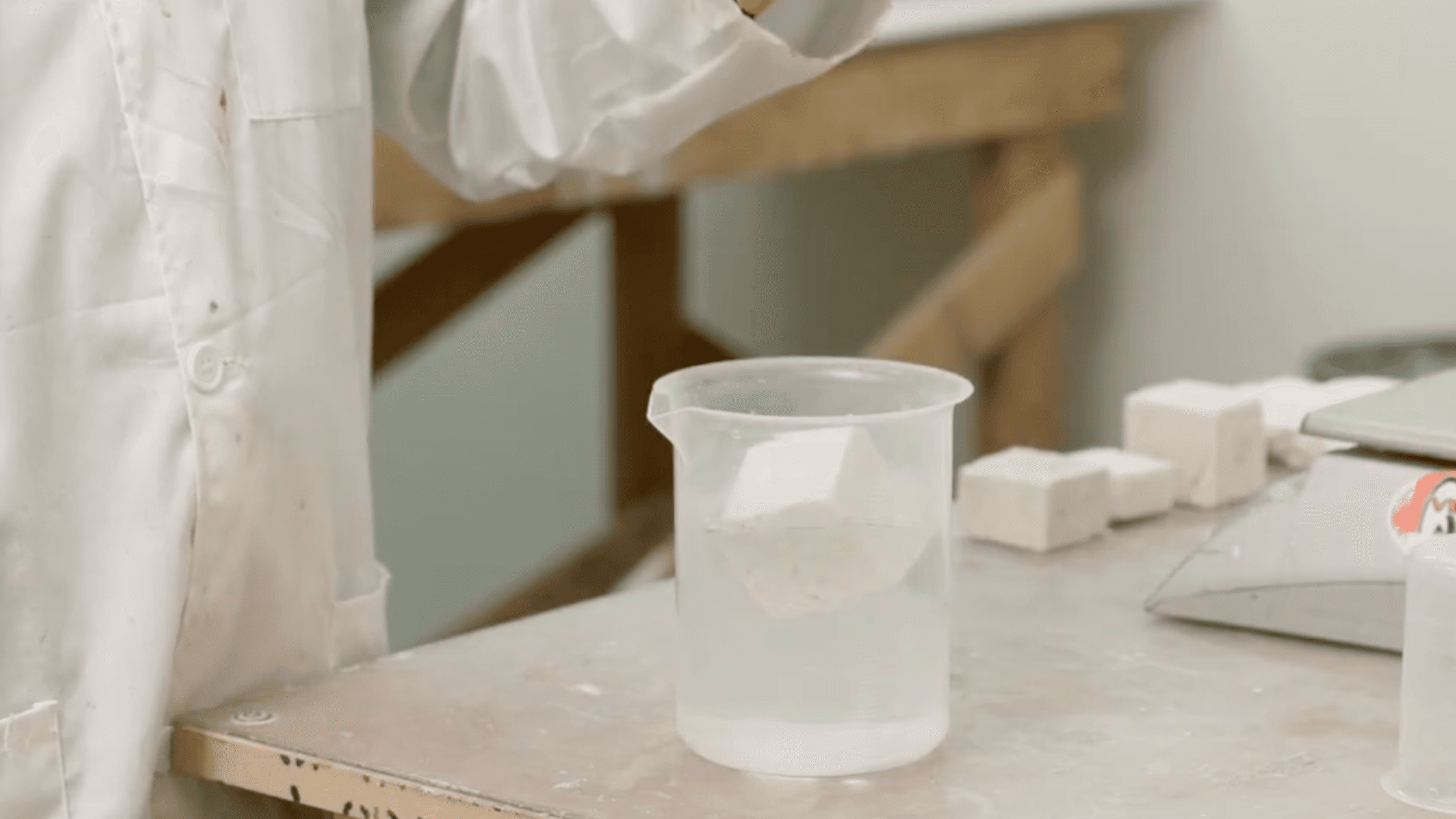

Creating materials that challenge industry standards requires rigorous testing. Dr Ali's lab operates on a simple principle: test, learn, refine, repeat.

Our team creates sample batches continuously, cures them under controlled conditions, then subjects them to extreme stress tests. Materials are exposed to 1,400°F flames, submerged in water for weeks, crushed in compression testing machines, and subjected to impact tests simulating hailstorms to falling trees. Then Dr Ali analyzes them with potent microscopes to figure out biochemically what's happening and how to improve on them.

But in-house testing is only the beginning. Geoship has completed extensive third-party certification testing with labs like Radco and Twining to validate performance claims. The factory-built housing certification from Episode 3 required proving these materials meet or exceed all relevant building codes.

"We test, we fail, we test again—that's how nature evolves, and so do we." — Dr Ali

Building with Nature's Blueprint

What Dr. Ali and the material science team have created opens multiple channels of innovation. These materials rethink what construction can be: completely non-toxic, highly crystalline compounds that may support biological wellbeing in ways we're just beginning to measure.

Imagine coming home to a structure that requires minimal maintenance, feels inherently comfortable, and actively contributes to your health. A living space that resonates with your biology rather than working against it.

This represents a new paradigm: not just shelter, but spaces designed to support both human and planetary health.

Many of you have been following this journey from the beginning. Whether you're an investor, a dome reservation holder, or simply someone who believes we can build better, thank you for making this possible.

See you in the next GeoJourney episode in a couple of weeks!

With gratitude,

Massimo Massarotto

Geoship Team